End-runner mill similar to edge runner mill is a mechanized form of mortar and pestle type size reduction equipment. A heavy-weight pestle rotates due to the friction of material present between mortar and pestle upon rotation of mortar driven by a motor at the base.

Principle of End Runner Mill:

The

principle of size reduction applied in these mills is crushing due to the heavyweight

of the stones or metal pestle and shearing force as a result of the movement of

these stones or metal. In the end-runner mill, a weighted pestle is turned by

the friction of material passing beneath it as the mortar rotates under powder

to be processed.

Construction of End Runner Mill:

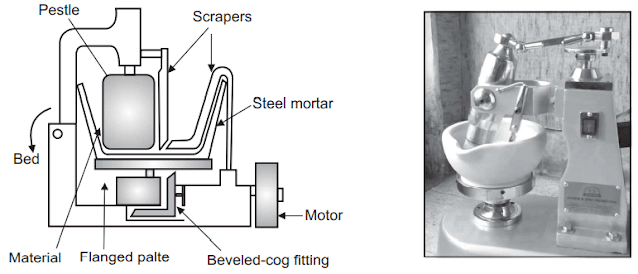

End-runner

mills are the mechanized forms of mortar and pestle-type compression

comminution. This milling equipment consists of a pestle made of either stone

or metal, connected by a shaft, Fig.1. The pastel rotates at its axis in a

shallow steel or porcelain mortar. The pestle is mostly dumb-bell shaped. The

mortar is fixed to a flanged plate at the bottom. It also consists of scrappers

at the center and alongside the circular pan. The pestle is mounted

horizontally and rotating against a bed of powders.

|

| Fig.1: End Runner Mill (a) Schematic (b) Mill Used in Practice |

Working of End Runner Mill:

The

material to be milled is fed into the center of the circular mechanical mortar

(pan) and is worked outwards by the action of the wheels and the mill is

operated. The pestle rotates against a bed of powders. Mortar revolves at high

speed and causes the pestle to revolve. Scrapers are employed in scraping the

material constantly from the bottom of the wheel and are fed back to the wheel

where it gets crushed further. Finally, the pestle is raised from the mortar

manually or automatically to facilitate emptying and cleaning.

Uses of End Runner Mill:

- It is used to reduce fibrous crude drugs to a fine size.

- It is used for grinding semisolid preparations such as ointments and pastes to a fine size.

- It is used for the uniform distribution of the contents in the viscous dispersion medium.

- It can be used for both wet and dry grinding of crude drugs.

Advantages of End Runner Mill:

- It has a simple design and thus cleaning and maintenance are easy.

- It utilizes less electrical power.

- It produces fine and sometimes very fine particles.

- Requires less attention during the milling operation.

- It has no problem of choking or clogging as it has no sieves for size separation.

Disadvantages of End Runner Mill:

- It runs only on the batch operation.

- It is not suitable for milling sticky materials.

- Unsuitable for drugs that are hard and unbroken or in slightly broken condition.

- Machine noise causes a lot of noise pollution.

- It requires scrapper adjustment intermittently.

Make sure you also check our other amazing Article on : edge runner mill