The bag filter is a mechanical device used in the quality of air in pharmaceutical production and other allied areas. In pharmaceutical production, very potent drugs such as hormones, vitamins, antibiotics, etc generate a lot of dust during processing which may be life-threatening to the operators. These processes include screening, blending, mixing, drying, granulating, tableting, compression, packaging, etc. It causes air pollution and chemical hazards. To avoid these unwanted situations the air is needed to be maintained clean. This is achieved by the use of filter bags. A fabric filter is a dust collection device made using a woven or non-woven filter bag that filters and collects the dust in the process gas. When the filter cloth is made into a cylindrical-shaped bag and suspended, it is referred to as a baghouse or a fabric filter.

Principle of Bag Filter:

The purpose of the filter bag to collect dust is based

upon the principle of filtration. The dust layer adheres to and is deposited on

the surface of the filter bag and the interior of the filter cloth (the primary

dust layer) filters and collects the dust contained in the process gas. The

fabric provides a surface for dust particles to get accumulated. The

accumulation or collection takes place by inertial or electrostatic

interaction, interception, and Brownian movement. Together these mechanism

results in the formation of the dust cake on the fabric surface.

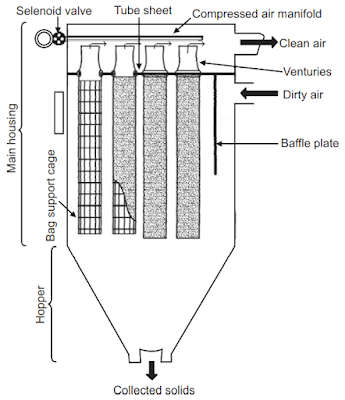

Construction of Bag Filter:

This equipment consists of a big metal vessel (baghouse)

with a series of fabric bags in compartments, Fig.1. The bags are made up of

woven cotton, wool, membranes, sintered metal fibers, or ceramic cartridges.

The selection is based upon the operating temperature and pressure and

stability of the filter medium to these conditions. Filter bags are suspended

in an invert position in the vessel. The length of bags varies from 2 to 10 m

with a diameter up to 40 cm. The open ends of the bags are attached to the

manifold. The number of bags in a vessel varies from 100 to 1000 or more

depending on the baghouse. In the bottom, a portion hopper is provided to

collect dust held by the filter.

Working of Bag Filter:

The processing gas enters through the inlet pipe that

strikes the baffle plate. This striking causes large particles to fall due to

gravity in the hopper at the bottom. Carrier gas then flows in an upward

direction and leaves through the bags leaving behind fine particulate matter on

its interior surface. Normally the filtration velocity of the process gas

passing through the filter cloth is about 0.3-2 m/min, and the pressure loss is

1-2 kPa. As the dust layer collected on the surface of the filter cloth becomes

thicker, the pressure loss of the filter cloth increases, so the collected dust

is intermittently removed. Removing the dust layer is carried out by mechanical

shaking, reverse pressure, or pulse jet. In most cases, the dust collection

efficiency of fabric filters is 99% or higher, and the dust concentration at

the outlet is less than 10 mg/m³. To achieve better efficiency filter bags are

cleaned, maintained, and changed intermittently.

Advantages of Bag Filter:

- A filter bag is the best method amongst all for removing fines from the air.

- Electricity consumption is low.

- It helps to maintain and protect a healthy environment.

- They are simple in construction and operation.

- It has versatility and an effective design.

- It helps to reduce housekeeping and better product quality.

- Filter bags have effective design according to American Ventilation System Standards

- High-quality filter bags have a trouble-free operation.

- It has a robust construction.

Disadvantages of Bag Filter:

- It has limitations for its operation due to high gas temperature and high humidity.

- The maintenance cost is high as the fabric used is costly.

- The characteristics of fabric change with operating parameters.

- Comparatively, it is large.

- Condensation of vapors and the presence of hygroscopic material reduce its efficiency.

Applications of Bag Filter:

- Bag filters are used in industries to separate dust particles from the air.

- These are used to clean the air in working areas.

- They are extensively used in large industries that produce different kinds of dust such as metals, cement, chalk and lime, ceramics, flour, and foundries.

- It is most commonly used in fluidized bed dryers.

Make sure you also check our other amazing Article on : Air Separator