|

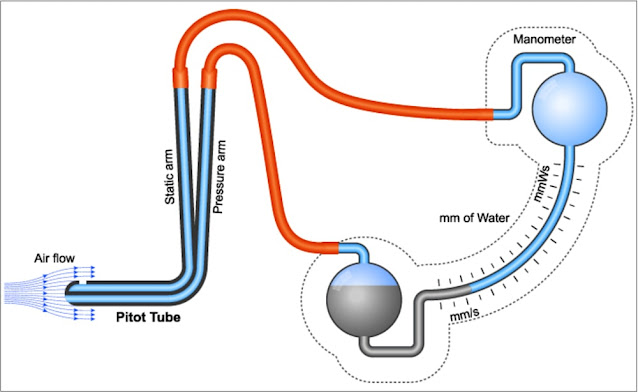

| Fig.1: Simple Pitot tube (a) Tube for Measuring the Stagnation Pressure (b) Static and Stagnation Tubes Together |

Working of Pitot Tube:

A pitot tube is a simple

round cylinder with one end opened with a small hole and the other end is

enclosed. The fluid flowing through the pipe enters the Pitot tube and rest

there. There is another chamber within the Pitot tube filled with fluid with

static pressure. A diaphragm separates both chambers. The differential pressure

is measured between both the pressures that give the dynamic pressure. The

difference in level between the liquid in the tube and the free surface becomes

the measure of dynamic pressure. The flow rate is calculated from the square

root of the pressure. The flow rate depends on the tube design and the location

of the static tap. The Pitot-static probe incorporates the static holes in the

tube system to eliminate this parameter.

The liquid flow-up the

tube and when equilibrium is attained, the liquid reaches a height above the

free surface of the water stream. The measurement of static pressure and the

impact pressure is performed through the attachment of a proper differential

pressure meter that determines flow velocity and thus the flow rate is

calculated. Since the static pressure, under this situation, is equal to the

hydrostatic pressure due to its depth below the free surface, the difference in

level between the liquid in the glass tube and the free surface becomes the

measure of dynamic pressure. Therefore, neglecting friction, we can write,

`p_0-p=\frac{\rho V^2}2=h\rho g ...(1)`

where, P0, P

and V are the stagnation pressure, static pressure, and velocity respectively

at point A, Fig. 1. (a).

For an open stream of

liquid with a free surface, this single tube is sufficient to determine the

velocity. But for a fluid flowing through a closed duct, the Pitot tube

measures only the stagnation pressure and so the static pressure must be

measured separately. Measurement of static pressure, in this case, is made at

the boundary of the wall, Fig. 1. (b). The axis of the tube measuring the

static pressure must be perpendicular to the boundary and free from burrs so

that the boundary is smooth and hence the streamlines adjacent to it are not

curved. This is done to sense the static pressure only without any part of the

dynamic pressure. A Pitot tube is inserted to sense the stagnation pressure.

The end of the Pitot tube measures the stagnation pressure, and the piezometric

tube, measuring the static pressure, may be connected to a suitable differential

manometer for the determination of flow velocity and hence the flow rate.

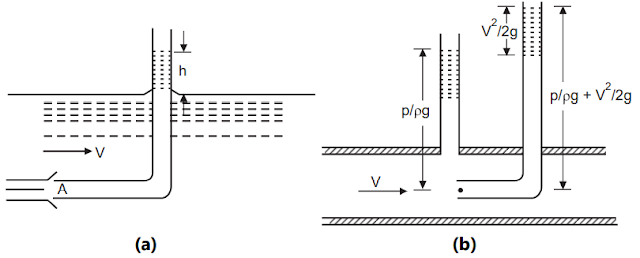

The tubes recording

static pressure and the stagnation pressure are combined into one instrument

known as Pitot static tube, Fig. 2. The tube for sensing the static pressure is

known as the static tube which surrounds the Pitot tube that measures the

stagnation pressure. Two or more holes are drilled radially through the outer

wall of the static tube into annular space. The position of these static holes

is important. Downstream of the nose of the tube, the flow is accelerated

somewhat with a consequent reduction in static pressure. But in front of the

supporting stem, there is a reduction in velocity and an increase in pressure.

The static holes should therefore be at the position where the two opposing

effects are counterbalanced and the reading corresponds to the undisturbed

static pressure.

|

| Fig. 2: Pitot Static Tube (I) Schematic (II) Real One Used In Practice |

`The\ flow\ velocity\ is\ given\ by\ V=C\sqrt{2\left(\frac{\triangle P}\rho\right)} ...(2)`

where ∆p is the

difference between stagnation and static pressures. Factor C takes care of the

non-idealities, due to friction, in converting the dynamic head into pressure

head and depends, to a large extent, on the geometry of the Pitot tube. The

value of C is usually determined from the calibration test of the Pitot tube.

Applications of Pitot Tube:

- It is widely used to measure the airspeed of aircraft, speedboat speed, and fluid flow measurement in industrial applications.

- Pitot tubes are mainly used for gas lines.

- These may be employed where the flowing fluid is not enclosed in a pipe or duct. For example, for measuring the flow of river water, or for measuring airflow in an airplane.

Advantages of Pitot Tube:

- A pitot tube is small and does not contain any moving parts.

- Low permanent pressure loss.

- Loss of head is negligible by insertion of Pitot tube.

- It is very cheap as compared to the venturi meter, orifice plate, and flow nozzle.

- Ease of installation into an existing system.

Disadvantages of Pitot Tube:

- The differential pressures produced are usually low, say of the order of 250 Pa, and so their sensitivity is low.

- Pitot tube requires higher flow velocity to produce measurable heads.

- It has small openings which get clogged due to passing solid particles and thus may disrupt normal reading as a result.

- It requires a high fluid velocity, of the order 15 m/s to produce a measurable differential pressure.

- There is no standardization of pitot tubes. Each Pitot tube is required to be calibrated for each installation.

Make sure you also check our other amazing Article on : Venturi meter