The moisture contained in

a material comprises all those substances which vaporize on heating and lead to

a weight loss of the sample. The weight is determined by a balance and

interpreted as the moisture content. As per this definition, moisture content

includes not only water but also other mass losses such as evaporating organic

solvents, alcohols, greases, oils, aromatic components, as well as

decomposition and combustion products. The moisture content is also called moisture

assays which is one of the most important analyses performed on most pharmaceutical

products. Water activity measurements parallel to the moisture content are also

an important parameter for the quality and stability of pharmaceuticals.

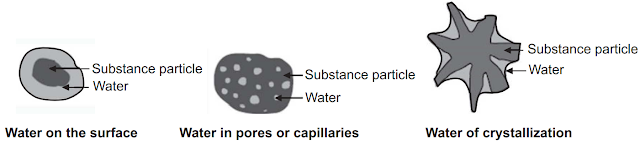

The moisture in products

can be present in different forms based upon the type of bonding with solids,

Fig.1. It is called ‘Free water’ when water is on the surface of the test

substance and it retains its physical form, ‘Absorbed water’ when water is

present in large pores, cavities, or capillaries of the test substance, and

‘Water of hydration’ occluded in lattice ions or water of crystallization

coordinately bonded to ions.

The loss on drying (LOD)

is the amount of water and volatile matters present in a sample when the sample

is dried under specified conditions. Moisture content (MC) is the quantity of

water contained in a material, such as raw materials, API, and blend.

| equation (1) |

| equation (2) |

Fig.1: Types of Bonding of Moisture in Pharmaceutical Products

The moisture content of

solid more than the equilibrium moisture content is referred to as free

moisture (water). It must be noted that during drying only free moisture is

evaporated. The free moisture content (FMC) of a solid depends upon the vapor

concentration in the air solid surface. The moisture contents of solid when it

is in equilibrium with given partial pressure of vapor in the gas phase is

called equilibrium moisture content (EMC). Similarly, the moisture content at

which the constant rate drying period ends and the falling rate drying period

starts is called critical moisture content (CMC). During the constant rate

drying period, the moisture evaporated per unit time per unit area of drying

surface remains constant and in the falling rate drying period the amount of

moisture evaporated per unit time per unit area of drying surface continuously

decreases.

When the water vapor

pressure of the air approaches the saturation water vapor pressure at the

temperature of the gas, the EMC of materials rapidly increases. At these

stages, the process undergone by the material is not only adsorption. Water

vapor begins to condense within the pore structures of the materials.

Theoretically, if the material is in contact with air that is 100 % saturated

for a very long period, all pores of the material should be filled with condensed

moisture. The EMC that corresponds to that hypothetical state is called the

saturation moisture content (SMC) of the material. But in practice, the rate of

this process becomes infinitesimally small at an EMC that is known as the

capillary saturation moisture content (CSMC) and is often substantially less

than the saturation moisture content referred to above.

Measurements

The moisture content is

determined by several direct and indirect methods.

(i) Direct Methods:

The direct methods include mainly thermogravimetric methods. The moisture

content can be determined by an oven method directly. The solid is weighed and

dried, then weighed again according to standardized procedures. In the

Thermogravimetric method, moisture is always separated. Thus, there is no

distinction made between water and other readily volatile product components. A

representative sample must be obtained to provide a useful moisture content

evaluation. Also, the moisture content of the product must be maintained from

the time the sample is obtained until the determination is made by storing it in

a sealed container. Thermogravimetric techniques can be used to continuously

measure the mass of a sample as it is heated at a controlled rate. The

temperature at which water evaporates depends on its molecular environment. The

free water normally evaporates at a lower temperature than bound water. Thus by

measuring the change in the mass of a sample as it loses water during heating

it is often possible to obtain an indication of the amounts of water present in

different molecular environments. For many solids, this method is mandatory,

particularly for granules. For granules, the moisture content is measured by

heating them in a hot air oven at a suitable temperature until the weight

becomes constant. For heat-sensitive materials vacuum is applied in the oven to

decrease the boiling point of the liquid.

(ii) Indirect Methods: Indirect

methods are developed to determine the moisture content rapidly. For example, the

use of modern heating measurement methods like infrared, microwaves, ultrasound,

and spectroscopy. These methods are developed due to requirements of rapid,

non-destructive, and precise moisture content determination. The indirect

methods are generally faster than the direct methods for moisture

determination. When done properly, the indirect methods can be accurate and

precise. However, the accuracy and precision of the indirect methods depend on

careful preparation and analysis of known standards to establish reliable

calibration curves. Indirect methods require a large capital investment in

equipment. Nevertheless, preparation of the standards and accurate calibration

curves must be verified by a specific direct method to establish a reliable

indirect method of instrumentation that can achieve accurate and precise

predicted values.

The methods for moisture

determination given in USP24 NF19 are the best, classical, and addresses only

the determination of moisture content. The U.S.P. offers two methods for the

determination of moisture content in solids:

- (a) Titrimetry (Karl Fisher titration).

- (b) Gravimetric (Thermal gravimetric analysis).

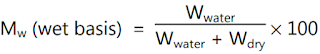

Moisture content is used

in a wide range of scientific and technical areas and is expressed as a ratio,

which can range from 0 (completely dry) to the value of the materials' porosity

at saturation. It can be given on a volumetric or mass (gravimetric) basis.

Moisture content is expressed as a percentage of moisture based on the total

weight (wet basis) or dry matter (dry basis). Wet basis moisture content is

generally used. The moisture content is expressed by the following formulae.

|

| equation (3) |

|

| equation (4) |

where,

- M = Moisture content on a percent basis,

- Wwater = Total weight as wet weight

- d = Total as dry weight

Based on the different

forms of moisture present in the material the method used for the measurement

of moisture may estimate more or less moisture content. Therefore, for

different pharmaceutical products, Official Methods of moisture measurement

have been given by agencies.

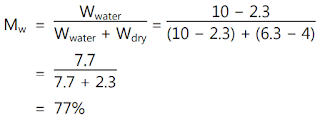

Example:

Accurately 10 g of granules are transferred into a 4 g container and after

drying the container with granules weighs 6.3 g. What is the percent moisture

content in the granules on a wet basis?

Solution:

Applications of Moisture Content Determination

Accurate percent moisture

content is essential for maintaining the stability of drug products. If a

product is too moist or too dry, it may not be suitable to be administered and

will not exert a desired therapeutic effect. Most pharmaceutical products contain

moisture. The percent moisture content is seldom of interest. Rather, it shows

whether a product intended for trade and production has standard

characteristics such as storage ability, agglomeration, microbiological

stability, flow properties, viscosity, etc. The dry substance content,

concentration or purity, compliance with quality agreements, the therapeutic

value of the product, and legal conformity are other important issues. In

addition, the determination of moisture content has the following applications:

- Freshness:

Fresh products have specified characteristic features. Moisture induces changes

in the state of the solid. As they age and begin to degrade, some dry out and

some pick up excess moisture and begin to mold.

- Labeling:

Pharmaceutical industries require a minimum or maximum percentage of moisture

in certain products for them to be packaged and labeled. If they don't fit these

standards, the products cannot pass the quality standards and are unfit for

commercial release. For example, freeze-dried products, hard gelatine capsules,

etc.

- Cost:

In processed pharmaceutical products, the percentage of water can determine its

final price. Generally, a product with more water will cost less.

- Processing:

The moisture affects the performance of excipients thus manufacturers and

physicians need to know the moisture content of the product to ensure that it

is processed and packaged in a safe, stable way.

- Quality:

Moisture content determines the way most products are appropriate to administer,

taste, feel and look. It is one of the important ways to measure product

quality.

- Shelf life: The physicochemical stability of bioactive agents alone and in combination with excipients is affected by moisture. Thus, the shelf life of the product depends on its moisture content at the time of packaging and the rate of moisture gain during storage. The stability of products depends upon the percent moisture in finished products.

Make sure you also check our other amazing article on : Drying