Suppositories can be prepared by one of three methods:

1. Hand Rolling

• It is the simplest and oldest method of suppository

preparation and may be used when only a few suppositories are to be prepared in

a cocoa butter base. It has the advantage of avoiding the necessity of heating

the cocoa butter.

• By triturating grated cocoa butter and active ingredients

in a mortar a plastic-like mass is prepared. The mass is formed into a ball in

the palm of the hands, then rolled into a uniform cylinder with a large spatula

or small flat board on a pill tile. The

cylinder is then cut into the appropriate number of pieces which are rolled on

one end to produce a conical shape.

• The suppository "pipe" or cylinder tends to crack

or hollow in the centre, especially when the mass is insufficiently kneaded and

softened.

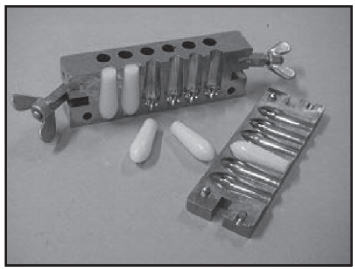

2. Compression Molding

Compression moulding is a method of preparing suppositories

from a mixed mass of grated suppository base and medicaments which is forced

into a special compression mould using suppository-making machines. The

suppository base and the other ingredients are combined by thorough mixing. The

base softens because of the friction in the process. A mortar and pestle can be used on a small

scale. On the other hand, large-scale manufacturing involves mechanically

operated kneading mixers and a warmed mixing vessel. In the compression machine, the suppository

mass is placed into a cylinder which is then closed. After that from one end

pressure is applied to release the mass from the other end into the suppository

mould or die. When the die is filled with the mass, a movable end plate at the

back of the die is removed and when additional pressure is applied to the mass

in the cylinder, the formed suppositories are ejected. The end plate is

returned, and the process is repeated until all of the suppository mass has

been used. When active ingredients are added, it is necessary to omit a portion

of the suppository base, based on the density factors of the active

ingredients.

3. Fusion Moulding

The Fusion Moulding process involves the following

steps:

• Firstly melting the suppository base.

• Then the drug is either dispersed or dissolved in the

melted base.

• The mixture is then removed from the heat and poured into a

suppository mould.

• The melt is allowed to congeal.

• Now the suppositories are removed from the mould.

Suppository Moulds

Small-scale moulds are capable of producing 6 or 12

suppositories in a single operation.

Industrial moulds produce thousands of suppositories per hour from a

single moulding.

Calibration of the Mould

The calibration of mould is necessary because the size of the

suppositories remains the same from a particular mould but their weight varies

because the density of the different types of bases and the medicaments used

are different. The first step is to prepare moulded suppositories from the base

material alone. The suppositories are combined and the average weight is

recorded. To determine the volume of the mould, the suppositories are melted in

a calibrated beaker, and the volume of

the melt is determined.

Lubricants used in Mould

Cocoa butter and glycero-gelatine bases are required

lubrication of moulds. This prevents the sticking of bases to the wall of the mould

cavity. It is also useful in the easy removal of suppositories from the moulds.

The lubricants form a film between the wall of the mould cavity and the base of

suppositories so, it prevents the adhering of bases to the moulds. The nature

of lubricants should be different from the nature of bases.

Lubricant must be compatible with medicament or adjuncts. In

industry, silicone fluid is used as a lubricant. Mould is lubricated using a

pad of gauze or muslin or with a small fairly stiff brush. Cotton wool is not

used because some fibres adhere to the mould. Excess lubricant can be removed

by inverting the mould on a clean white tile.

Following lubricants may be used for the preparation of

theobroma oil suppositories.

Examples:

(a) For cocoa butter bases

Alcohol(90%)- 50 ml

Glycerol - 10 ml

Soft soap - 10 gm

(b) For glycerol-gelatin base

Liquid paraffin or Arachis oil is used as a lubricant.

Packaging

Suppositories must be packed in such a manner that they do

not touch each other.

Poorly wrapped and packaged suppositories can lead to

staining, breaking or deformation by melting caused by adhesion. Suppositories

usually are foiled in tin or aluminium, paper or plastic strips. Overwrapping

is done by hand or machine.

Hand packing yields a non-uniform product so machines are

utilised to overcome this problem and machines can wrap 8000 suppositories per

hour.

Storage

Suppositories should be protected from heat, preferably by

storing in the refrigerator.

Polyethylene glycol suppositories and suppositories enclosed in a solid

shell are less prone to distortion to temperature slightly above body

temp.

Labelling

Suppositories should be labelled as:

(a) "STORE IN A COOL PLACE"

(b) "FOR EXTERNAL USE ONLY"

(c) "NOT TO BE TAKEN ORALLY".