An air separator is usually a mechanical device with a large metal box containing a blower, heating or cooling elements and filter racks or chambers, sound attenuators, and dampers. Air separators are usually connected to a duct of a ventilation system that distributes the air and fine particles.

Principle of Air Separator:

The air separator works on the same principle as the cyclone separator. The cyclone separators sometimes are not efficient in separating

powders that contain very fine size particles. In such situations, an

additional provision is made that combines the current of air with the

centrifugal force. This causes fines to separate along with air and coarse

particles to be thrown away by centrifugal force which is collected at the

bottom.

Construction of Air Separator:

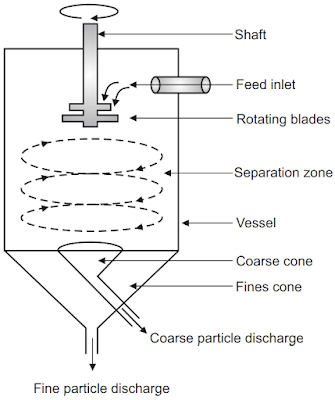

It consists of a vertical metal cylindrical vessel

with the conical base at the bottom, Fig.1. The feed inlet is fitted

tangentially at the upper part of the vessel. The outlet for collected solids

is at the base of the conical portion whereas the fluid outlet is at the center

of the top portion. The fluid outlet pipe extends down below the inlet section

to avoid air short-circuiting directly from the inlet into the outlet. The

rotating disc and rotating blades are fitted on the shaft are placed at the

center of the vessel. It has two separate outlets at the bottom for finer and

coarser/heavy particles.

Working of Air Separator:

The feed enters through the inlet tangentially in the

upper part of the vessel. Feed falls on the rotating blades. The rotating

blades produce an air jet in the direction indicated in Fig.1. The fine

particles are blown away on the walls by the centrifugal force generated with

the air jet and are collected at the bottom. The coarser particles due to their

large mass travel less distance from the center of the separator and fall in

the coarse particle collection zone which is collected at its discharge.

Advantages of Air Separator:

- It is easy to install.

- The rotor speed, as well as airflow, is adjustable.

- It has a high production output.

- It is easy to clean and maintain.

- It is superior to the sieving method in terms of output and quality of products.

- It is used in batch as well as continuous mode.

Disadvantages of Air Separator:

- If particles are too fine (<5 µm) its efficiency decreases.

- It is not suitable for wet and sticky materials.

Applications of Air Separator:

- It is used as a dust collector in many processes to either recover valuable granular solid or powder from process streams.

- It can be used to separate sub-micron size particles that cannot be handled by sieving.

- It is often used as an air pollution control device to maintain or improve air quality in pharmaceutical production areas.

- It can be used as mist collectors to remove particulate matter in the form of fine liquid droplets from the air to improve or maintain the quality of air in the workplace environment.

- It can be used to remove granular solid pollutants from exhaust gases before venting into the atmosphere.

- It can be used for the collection of metalworking fluids, and coolant or oil mists.

Make sure you also check our other amazing Article on : Cyclone Separator