A fluidized bed dryer

(FBD) is well known and widely used equipment in pharmaceutical manufacturing.

It is used in the granulation process for drying the material to get desired

moisture content in the granules or powders required for perfect compression of

tablet formulation. Conventional fluidized bed dryers include batch fluidized

bed dryers, semi-continuous fluidized bed dryers, well-mixed continuous

fluidized dryers, and plug flow fluidized bed dryers.

Principle of Fluidized Bed Dryer

The equipment works on a

principle of fluidization of the feed materials. In the fluidization process,

hot air is introduced at high pressure through a perforated bed of moist solid

particulate. If air is allowed to flow through a bed of solid powdered material

in the upward direction with a velocity greater than the settling rate of the

particles, the solid particles are blown-up and remain suspended in the air

stream. At this stage, the solid bed looks like the boiling liquid; therefore

this stage is called fluidized. Heat transfer is accomplished by direct contact

between the wet solid and hot gases. The use of hot air for fluidizing the bed

increases the drying rate of the material. The vaporized liquid is carried away

by the drying gases. Sometimes to save energy, the exit gas is partially

recycled.

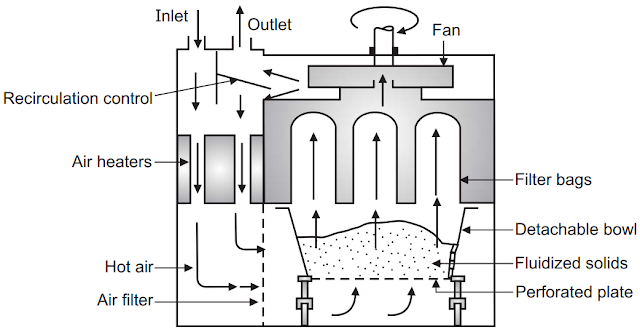

Construction of Fluidized Bed Dryer

A fluidized bed dryer

contains a stainless steel chamber having a removable perforated bottom known

as the bowl. A typical FBD consists of the air handling unit, product

container, exhaust filter, exhaust blower, control panel, air distribution

plate, spray nozzle, and solution delivery. The appropriate choice of

distributor used during the drying process ensures uniform and stable

fluidization. The pressure drops across the distributor must be high enough to

ensure good and uniform fluidization.

|

| Fig.1: A Typical Vertical Fluidized Bed Dryer |

Working of Fluidized Bed Dryer

Material to be dried is

placed in the bowl-type vessel. Air is introduced from the top and heated at the

required temperature by the heaters. The air is filtered through the filter and

then passes through the bed of the material at the bottom. The airflow is

generated by the fans fitted at the top of the equipment. The airflow rate and

the operating temperature are adjusted by the control panel. As the flow of air

increases, the bed expands and particles of powder start to rise in a turbulent

motion. Regular contact with air causes the material to dry. The air leaving

the FBD passes through the filter to collect the fine particles of the

material. A fluidized bed dryer has a high drying rate and the material is

dried in a very short time. Material remains free-flowing and uniform. FBD bags

have a finger-like shape to increase the volume of the drying bed that helps to

increase the drying rate and decrease the drying time.

Advantages of Fluidized Bed Dryer

- FBD has high rates of moisture removal due to excellent air-particle contact which results in high heat and mass transfer rates thus has fast and homogeneous drying.

- High thermal efficiency is usually achieved if part of the thermal energy for drying is supplied by the internal heat exchanger.

- It has low capital and maintenance costs.

- Minimum contact time for drying is best suited for heat-sensitive products.

- FBD is highly efficient in material drying to the desired level.

- Handling FBD is easy due to the simple system control panel and thus requires less labor.

- FBD designs come in a wide range of capacities and sizes.

- It shows no hot spots on the final products.

- It is suitable for both continuous and batch material processing.

Disadvantages of Fluidized Bed Dryer

- The high-pressure drop requires more energy to suspend particles.

- Requires increased air handling due to extensive recirculation of exhausts air for high thermal efficiency operation.

- It has poor fluidization and low flexibility in operation, especially if the feed is too wet.

- Not the best choice of equipment when organic solvents are to be removed during drying.

- Non-uniform product quality for certain types of materials.

- There may be entertainment of fine particles.

- It has a high potential for attrition and in some cases agglomeration of fine particles.

- The conventional hot air FBD is not a good choice of dryer when handling toxic or flammable solids since there is a danger of fire or explosion if flammability limits are exceeded.

- It has a possibility of product loss.

- There are high chances of electrostatic force build-up.

- Using FBD drying of sticky material is quite difficult.

Applications of Fluidized Bed Dryer

- Fluidized bed dryers are used in chemical, pharmaceutical, food, dairy, metallurgical, dyes, and other process industries for drying of powders, mixing of powders, and agglomeration of various materials such as powders, tablets, granules, coals, fertilizers, plastic materials, etc.

- This process is fast is used in the granulation of pharmaceutical powders.

- Fluidized bed coaters are used widely used for coating powders, granules, tablets, pellets, beads that are held in suspension by a column of air.

- FBD is used for several purposes, such as fluidized bed reactors (types of chemical reactors), solids separation, fluid catalytic cracking, fluidized bed combustion, heat or mass transfer, or interface modification, such as applying a coating onto solid items.

- The three types (Top spray, Bottom spray, Tangential spray) of FBD are mainly used for aqueous or organic solvent-based polymer film coatings.

- Top-spray fluidized bed coating is used for taste masking, enteric release, and barrier films on particles/tablets. Bottom spray coating is used for sustained release and enteric release and Tangential spray coating is used for SR and enteric coating products.

- FBD is efficiently employed for applications in chemical, pharmaceutical, dyestuff, foodstuff, dairy, and various other process industries with the spray dryers and granulation systems for effective drying, mixing, granulation, finishing, and cooling of powdered substances.

- It has been preferred over rotary dryers for drying and cooling a wide range of polymer materials which require precise control of residence time and temperature for effective processing.

- It is used for drying moist dibasic calcium phosphate anhydrous (DCPA).

- It is suitable for the formulation, development, and production of clinical materials.

- The modified versions of FBD are used as precision granulators, top spray granulators, spray drying granulators, and granulator coater.

- Various types of modified fluidized bed dryers have been developed and are applied in many industrial processes to overcome some of the problems encountered while using conventional fluidized bed dryers and for a drying process.

(A) Batch Type FBD:

(i) Reverse turning bed

type: In this FBD, by turning the air dispersion plate (the

reverse turning bed) in a 90° direction with the control motor, all the dried

material can be discharged at once.

(ii) Rotating discharge

type: Dried material is discharged by opening the discharge

gate equipped at the side of the dryer. Since the perforated plate is used as

the air dispersion plate, the air inside the equipment whirls and pushes the

dried material out from the discharge gate.

Example:

Vertical FBD with granulating option

Characteristics of batch FBD:

- The residence period of the dried material can be controlled which results in uniform drying.

- It is most suitable in the case where accurate control of the residence period is required at the decreasing rate drying zone.

- Small destruction of the particle occurs therefore suitable for granular or crystallized material.

- An easy operation can be achieved by automatic control of material feeding, drying discharging, etc.

- When multiple stage system is adopted, the exhaust air heat can be used efficiently.

(B) Continuous Type FBD:

Residence time in any

drying zone is dependent on the length of the zone, the frequency, and the

amplitude of the vibration and use of dams. Heat transfer units such as tubes

or plates are built inside the equipment. These units supply 60-80 % heat

necessary for drying.

Example:

Horizontal vibrating conveyor fluid bed dryer

Characteristics of continuous FBD:

- The materials with relatively high moisture content can be dried.

- At and after a second drying chamber piston flowability can be achieved by arranging numbers of the partition plates as per the required residence period.

- The perforated plate in the fixed direction ensures easy discharging.

- It causes small destruction of particles and thus is suitable for drying granules or crystalline materials.

- In multiple zones, fluid bed dryers heating and cooling occur in the same unit.

- Each zone has independent control for temperature, dew point, and velocity of air.

- By adjusting the weir height for each zone, residence time can vary up to four-fold in the unit.

Make sure you also check our other amazing article on : Spray Dryer