Tray drying is a batch process used to dry materials that are liquid or wet cake. Tray drying works well for material that requires more gentle processing or cannot be atomized in an airstream due to viscosity. This dryer is well utilized for drying wet products like crude drugs, chemicals, powders or the granules, etc. It is the most conventional dryer used very widely and still being used where the moisture content is more and where the product has to be dried at low temperature for long hours.

Principle of Tray Dryer

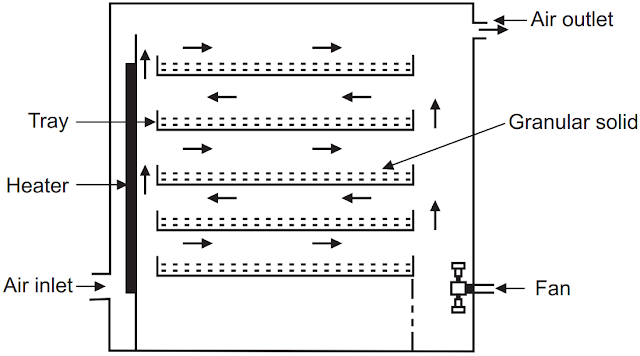

A laboratory oven is the

elementary form of tray dryer which contains a cabinet with a heater at the

bottom. The values of these ovens are very less because of their uncontrollable

heat transfer or humidity. When we fit a fan in the oven, the circulation of

the forced hot air gets started. This process is beneficial for reducing the

local flour concentrations and also for increasing the heat transfer. In the

direct circulation form, the air is heated and then focused on the object in a

controlled flow. The material to be dried is dispersed on the tiers of the

trays. For the circulation of the air across the drying materials, the screen

in trays are perforated and lined with paper. A limited amount of heat is

provided to every shelf at that time when the air passes over it to provide the

latent heat of vaporization. This kind of dryer provides proper control of

humidity and temperature.

Construction of Tray Dryer

Tray dryer can be

electrically or steam heated. It consists of any number of trays that varies

with customer requirement. It is fabricated out of a rigid angle iron frame

with double-walled panels insulated with the best quality compressed fiberglass

and with a rigid door fitted with strong hinges and the best-chosen locking

system. There may be a facility to circulate hot air such as fans. A control

panel is fixed in the front of the oven to facilitate easy operation. It has a

large functional space and is made of mild steel and in good finishing outside

with synthetic enamel color and inside painted with heat resistant paint to

resist temperature up to 300 oC.

Working of Tray Dryer

Tray dryer is widely used

in the pharmaceutical industry. The material to be dried is placed on the

trays. The heat in the dryer is produced by the heater along a side or at the base.

Other than the hot air generated by the oven, the other method is to employ

radiator coils that use steam for heat circulation. During the heating process,

the material to be dried is spread out on the trays. The heated air is directed

to flow in a circulation form. It flows over the material in the trays in a

controlled flow. Trays can have a solid, perforated, or wire mesh base. A paper

lining could be used to reduce the chances of contamination through contact

with the tray. The efficiency of the dryer depends on the recirculation of the

hot air. Apart from a regular supply and the presence of heated air, it also

depends on the supply of fresh air. The fresh air is combined with the heated

air in a fixed proportion for efficient performance. Such regulated drying is

important to ensure uniform drying in the dryer at the bottom as well as at the

top. Apart from the double-walled construction insulation is achieved by

heating coils.

Advantages of Tray Dryer

- It is operated on batch mode so each batch can be handled as a separate entity.

- It is energy efficient dryer as it consumes less energy.

- It’s simple to use and clean.

- Tray dryer is available in different sizes thus capital cost can be controlled.

- Chamber walls are heated externally thus preventing condensation.

- It is available in a unique single chamber and multi-chamber design with the lowest leakage.

- It has excellent surface contact between tray and shelf.

- It is the best option in small-scale production and drying valuable pharmaceutical materials such as drying wet lumpy solids and wet cakes.

- It has a heavy-duty hollow shelf design with all connections outside the chamber.

- Operating parameters can be controlled more easily.

- Using vacuum systems tray dryers can be best suited for drying heat-sensitive materials.

Disadvantages of Tray Dryer

- As it is operated at low to intermediate temperatures the process is time-consuming.

- Only a fraction of the solid particles is directly exposed. Heat transfer and mass transfer are comparatively inefficient.

- It provides a tendency to over-dry contents in the lower trays.

- The operation is long during the cycle (5 to 45 h per batch) and expensive to operate due to the high labor requirement for loading and unloading.

- Plastic substances can also be dried using this dryer.

- It is not suitable for large-scale production.

- Thermolabile drugs, liquids, slurries, cannot be dried.

Applications of Tray Dryer

- Tray dryer has industrial applications such as in chemical and pharmaceuticals.

- Sticky materials, granular mass or crystalline materials, precipitates, and paste can be dried in a tray dryer.

- It has been used in agricultural drying because of its simple design and capability to dry products at high volume.

Make sure you also check our other amazing article on : What is a Drying Curve?